A unique solution, hand crafted to order. You dream it, we make it.

Since the late seventies the doors of TAROX have been open to customers far and wide, helping to solve their braking problems. In this time we have seen many wonderful vehicles, from true icons such as the Lamborghini Miura and Diablo to the Nissan GTR, with many performance cars and exotica in-between.

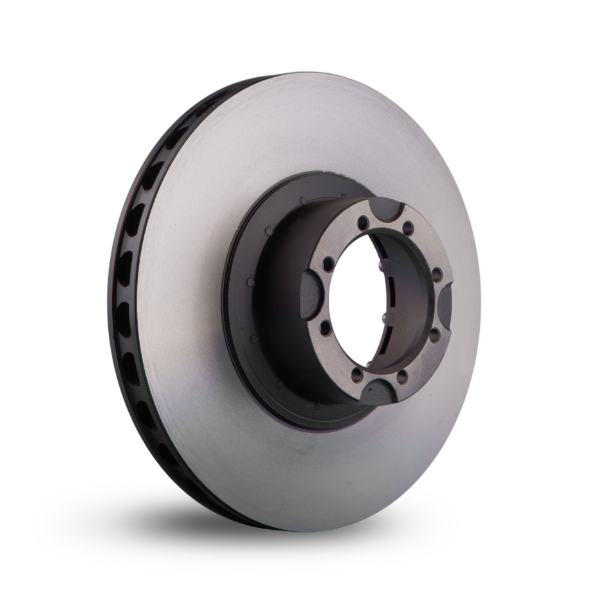

- Heat treated and hand finished for the unmistakable TAROX finish

- Flexible manufacturing allowing one off orders of discontinued parts

- Unique process of CNC machining from a single slice of steel billet

- The highest quality treated steel ensures greater performance and longevity

- Available for both high performance modern vehicles and classic cars

The TAROX bespoke range is a unique service which has grown in popularity with the increase in sports saloons and sports cars’ use of a racing style brake systems and the decline in availability of parts for classic and rare models. The use of sliced rolled steel billets allow us to work without relying on cast, enabling the recreation of any brake disc, whether it is a small single piece disc with a plain surface for a concourse Lamborghini Miura or a two piece bell and rotor replacement for an Audi R8. 40 years of braking experience ensures we will find a solution for your braking needs.

Using steel billets as the foundation from which the manufacturing can begin does not only afford us manufacturing flexibility – the gains in performance are significant. When finished, a pair of TAROX bespoke discs will have Ultimate Tensile Strength of 57kg per square millimeter; more than double the CEE standard of 25kg.

Modern High Performance Solutions

TAROX high performance disc options are available for the world’s fastest vehicles. On high performance models where braking performance is huge, so is OEM replacement cost. TAROX’s unique material and manufacture technology affords increased performance at more pleasant price point.

With heat dissipating 2-piece upgrade options and billet high-wear applications, TAROX bespoke discs address key weak points in the original disc design. From supercars to hot hatches, owners agree – TAROX bespoke high performance discs are an advantage in all aspects.

Fixed, semi-floating, and fully-floating configurations are all carefully considered by our engineers when developing a new disc.

Classic Marques & Concourse Solutions

The TAROX bespoke disc range also extends to older models and vehicles for which replacement parts have been discontinued. Expert product development ensures perfect fitment on even the most valuable and rare vehicles.

Using CNC turned billets, we can replicate any brake disc no matter how old the vehicle. TAROX engineering and design quality updates older braking systems with modern performance and reliability. For those who want only the very finest components look no further than TAROX.

Made from steel billet

TAROX can manufacture a unique set of brake discs from specifically chosen rolled steel billets. When the rolled billet is sliced we can begin to CNC the required dimensions. Once the raw brake discs have been manufactured they are then subjected to heat treatment and hand finished giving them the unmistakable TAROX finish.

Using steel billets as the foundation from which the manufacturing can begin does not only allow us a manufacturing flexibility the gains in performance are significant. When finished, a pair of TAROX bespoke discs will have UTS (Ultimate Tensile Strength) of 57kg per square millimeter; more than double the CEE standard of 25kg.

Heat treated for resilience

All TAROX discs are subject to structural stress relieving heat treatment to deliver the best performances in all conditions. Unique to TAROX, this overnight process has been perfected by over 40 year of experience and keeps the disc more stable at extreme temperatures greatly reducing common problems such as warping, cracking and fade. The heat-treatment process is as essential on our bespoke discs as it for our regular cast discs. The heat cycles we apply to the steel ensure it is ready for its life as a high performance brake disc.

Manual grinding

Finally after being machined, the surface of each disc is manually ground on bespoke machinery to a tolerance approaching 0.015mm creating a perfectly level surface. This ensures that the discs are perfectly true and improve disc and pad ‘bedding in’.

FUN FACT: the machinery used in this final stage of production is re-calibrated after every three cycles.

What if it floats?

TAROX floating brake discs use stainless steel bobbins to allow the working steel section of the rotor to expand and contract independently of the aluminium hub. Our semi-floating arrangement, as used on most road applications, allows the rotor to expand and contract radially, reducing the possibility of warping and helping to mitigate heat transfer to vital vehicle components such as wheel bearings and CV joints. Our fully floating arrangement allows for lateral axial movement in addition to radial expansion. This feature reduces brake pad ‘knock off’ for a more immediate pedal response – ideal for cars with larger diameter setups driven in competition.

For both systems we engineer the ‘float’ into the harder wearing steel part of the assembly rather than the softer aluminum hat section like many competitor products. This increases the lifespan of the alloy hat allowing you to re-use them once the rotors have worn out.

Italiano

Italiano