TAROX high performance rotors, the range explained.

Since the early 1980s TAROX Performance Brake Rotors have been associated with absolute quality. TAROX were first to the market with aftermarket solutions for high performance brake rotors. Inspired by motorsport endeavors TAROX soon became “the original groovers”, adding slots (often called grooves in our native Europe) to brake rotors to improve performance.

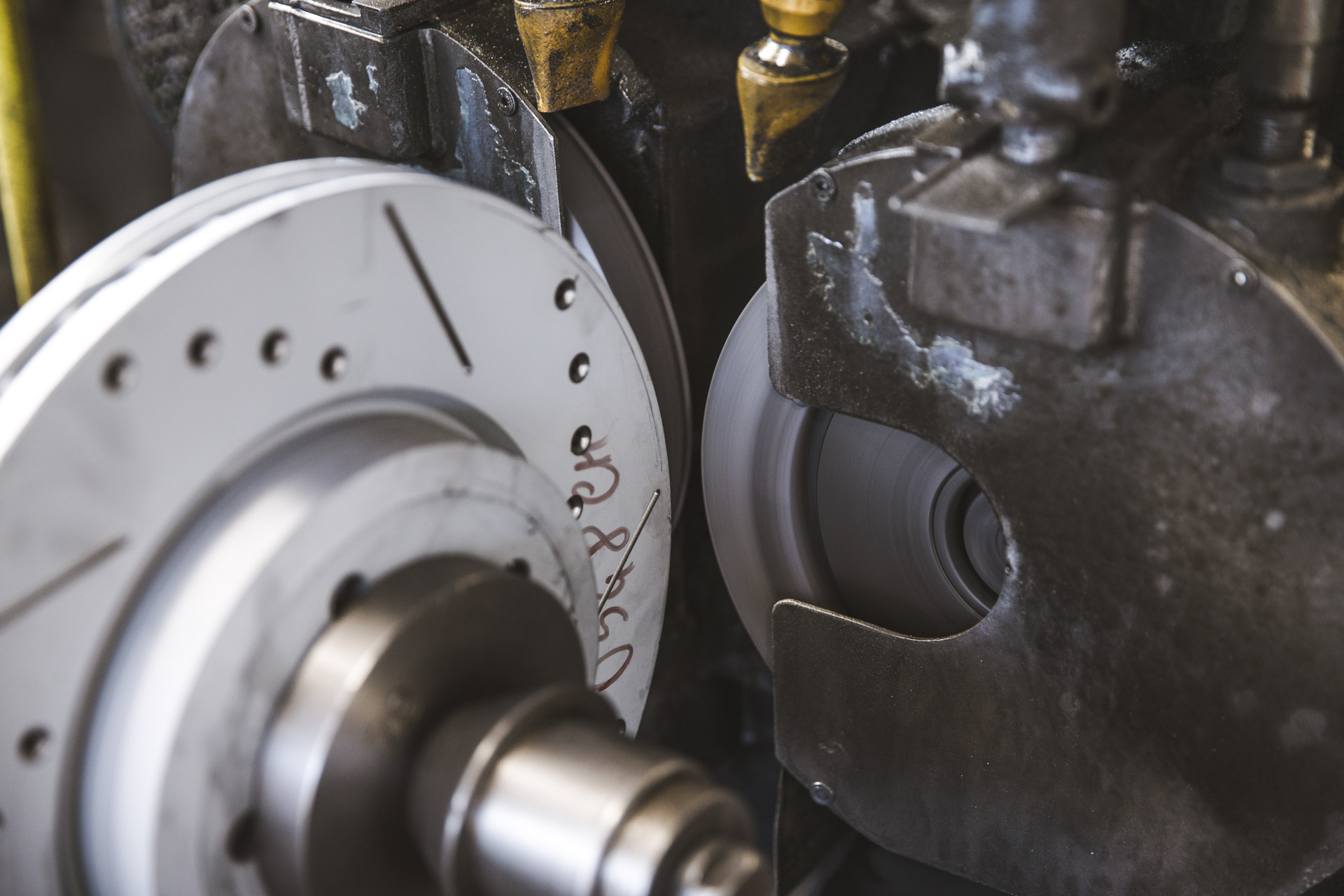

All TAROX rotors begin as a blank cast, selected to the highest levels of accuracy and are uniquely subjected to structural stress relieving heat treatment at the end of each machining phase. The result is a high performance, hard wearing, supreme-quality brake rotor, the product of more than 30 years experience.

Facing is performed on CNC turning machines or – in the case of G88 rotors – on in house custom built machinery. Another distinguishing feature of TAROX brake rotors is their perfectly level surface, machined to a tolerance approaching 0.015 mm (0.0006″). This is achieved during the final finishing of the braking surfaces on grinding machines; each rotor is ground individually by a specialized operator resulting a that distinctive shining look.

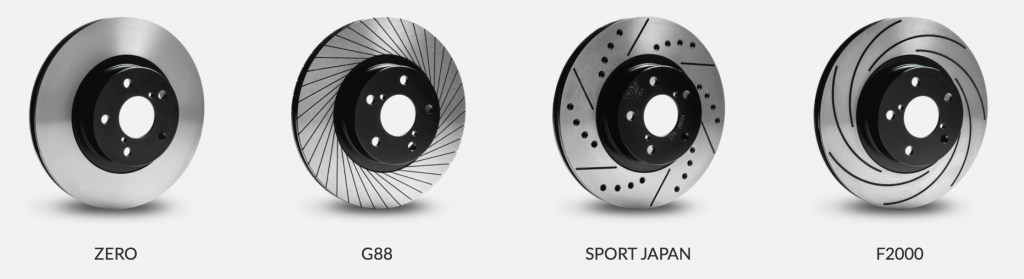

Today, TAROX offer four variations in performance rotor, Zero, F2000, G88 and Sport Japan.

But why does this matter? Well a better rotor gives better performance, but it can also provide better wear characteristics. A more thermally stable material allows TAROX brake rotors to work harder, for longer. What’s more, each of the TAROX designs are tailored to meet specific performance requirements, allow us to explain…

Although plain in appearance, the ZERO discs are far from plain. TAROX Zero rotors are made from special high grade casts submitted to several levels of heat treatment. An outstanding resistance to high temperatures prevents warping and cracks.

The final hand finishing leaves them incredibly smooth allowing them to mate to pads efficiently, increasing life of the rotor and pad. The ZERO has proved highly successful in both circuit racing – where regulations do not allow modified brake systems – as well as group N competition. Regular use in international Endurance racing saw the Zero last up to twice as long as a regular plain rotor.

The F2000 transcended from a racing specific rotor into the road range. With the big power increases of modern day sport saloons and hot hatchbacks, combined with the increasing popularity of track days, there was a demand for a disc which could cope with high operating temperatures and gruelling conditions. The F2000, first developed for use in touring cars over 15 years ago and often found in the TAROX range of big brake kits, has forged a reputation as the toughest performance aftermarket brake rotor available.

Spiral slots are the perfect compromise of cooling and integrity: the F2000 will feature between 7 and 9. As with all TAROX rotors, the F2000 is manufactured using only the highest quality high carbon TUV approved castings and features the unique TAROX heat treatment for strength and durability, final hand balancing for the smoothest finish ensuring perfect contact and a quick bedding-in process and a final, anti-rust treatment.

The G88 is the most unique of our brake rotors and unmistakably TAROX. The reason for this unique appearance is the custom built machinery, designed and made by TAROX to ensure the slots on the G88 are like no other.

The G88’s slots feature an edge to edge design, ensuring absolute maximum dissipation of heat, while incorporating a chamfered leading edge, which ensures that the life of the brake pad is not decreased.

The unique slots allow the G88 to run cooler than any other performance brake disc tested against it. Its unique looks and unrivaled performance on the road have led it to be a firm favorite for street tuning since its conception in 1988.

As with all of the TAROX performance rotor range, the G88 only uses the highest quality European high carbon TUV approved castings and features the unique TAROX finishing processes of heat treatment for strength and durability, hand finished balancing for a perfectly flat surface allowing for easy bedding-in and a perfect contact patch for maximum braking efficiency and a final, anti-rust treatment.

As the name implies the Sport Japan was originally designed for the Japanese market, where performance and tough looks are essential.

Sport Japan rotors are one of the only aftermarket performance rotors to still feature fully drilled holes, which is one of the most effective ways of venting hot gases from the brake surface. Although effective, this is an aggressive method of dissipating heat. To ensure ultimate performance and durability all Sport Japan rotors feature countersunk holes strategically placed in order not to affect the rotor’s structural integrity. This method is much more effective than a dimple, as the gas actually leaves the rotor’s surface into the ventilation channels in the rotor center and away from the rotor surface, ensuring the rotor runs cooler for longer.

An additional 6 slots on the braking surface act like a wiper, keeping the brake pad from glazing and removing excess dust while providing additional cooling. All Sport Japan rotors are made from the highest quality high carbon TUV approved castings, and feature our unique finishing processes of heat treatment for strength and durability, perfect final balancing to within 0.01mm (0.0004″)(for a perfect contact patch and quick bedding-in and a final, anti-rust treatment.

To find out more about TAROX rotor applications for your car, click here: http://www.tarox.com/us/product_cat/brake-rotors/

Previous article« Autosport Performance and Tuning Show 2019

Next articleAre you making these eight, common mistakes when driving on track? »